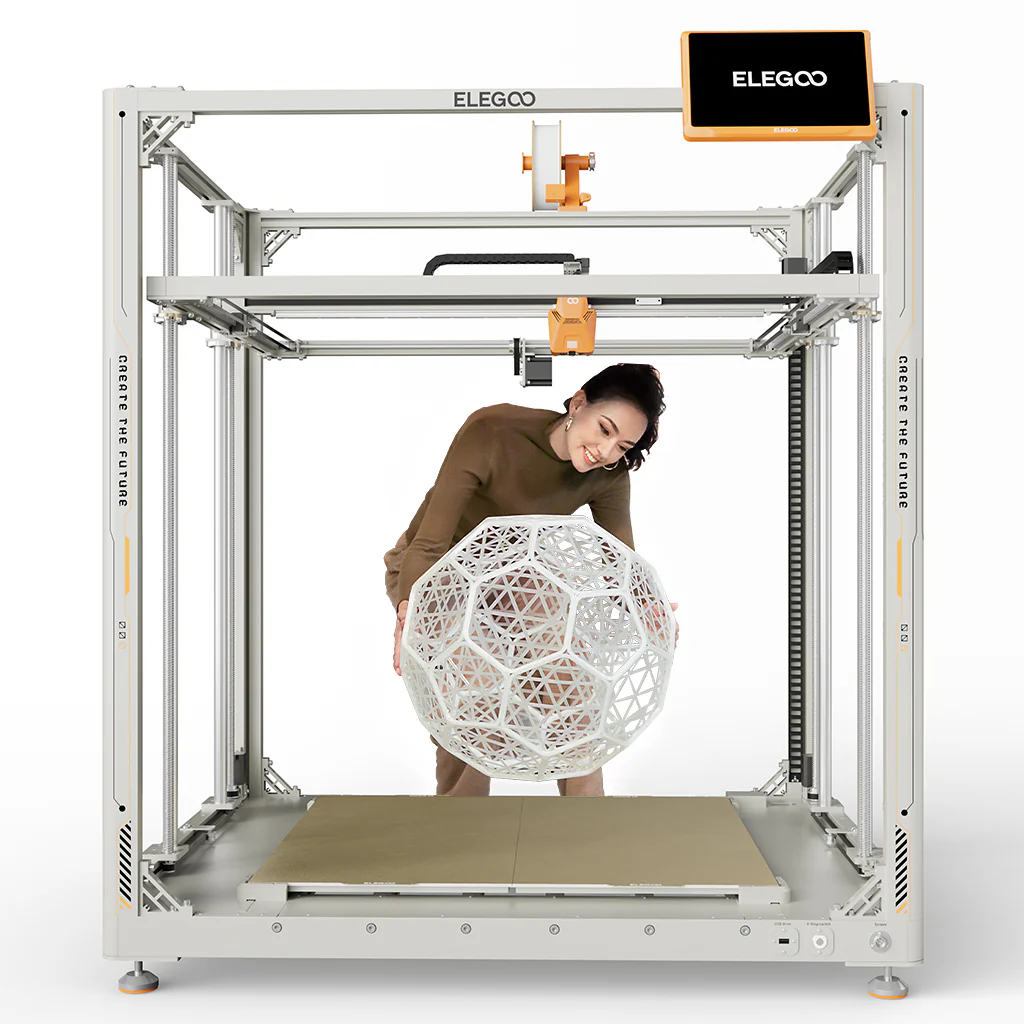

Gigatic in Size

With a build volume of 800mm x 800mm x 1000mm, the industrial-grade FDM printer not only meets the user’s printing needs for oversized models, but also reduces the need to cut models into smaller sections for efficient printing.

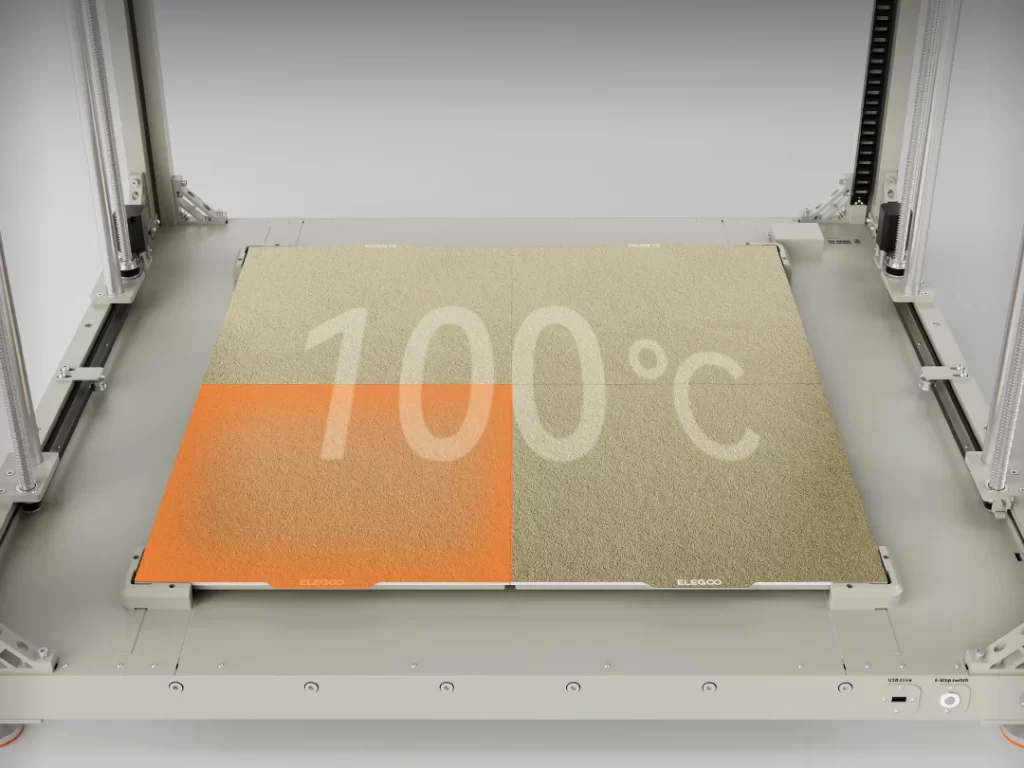

Efficient Heating Bed

The heated bed consists of four independent (410*410mm) PEI magnetic high-temperature platforms with a maximum temperature of 100°C.

The four platforms can be heated simultaneously to reach 100°C over the entire area in 17 minutes (Ambient temperature: 25℃).

The platform where the model is located can also be automatically recognized and heated independently, or manually and independently controlled for increased energy efficiency.

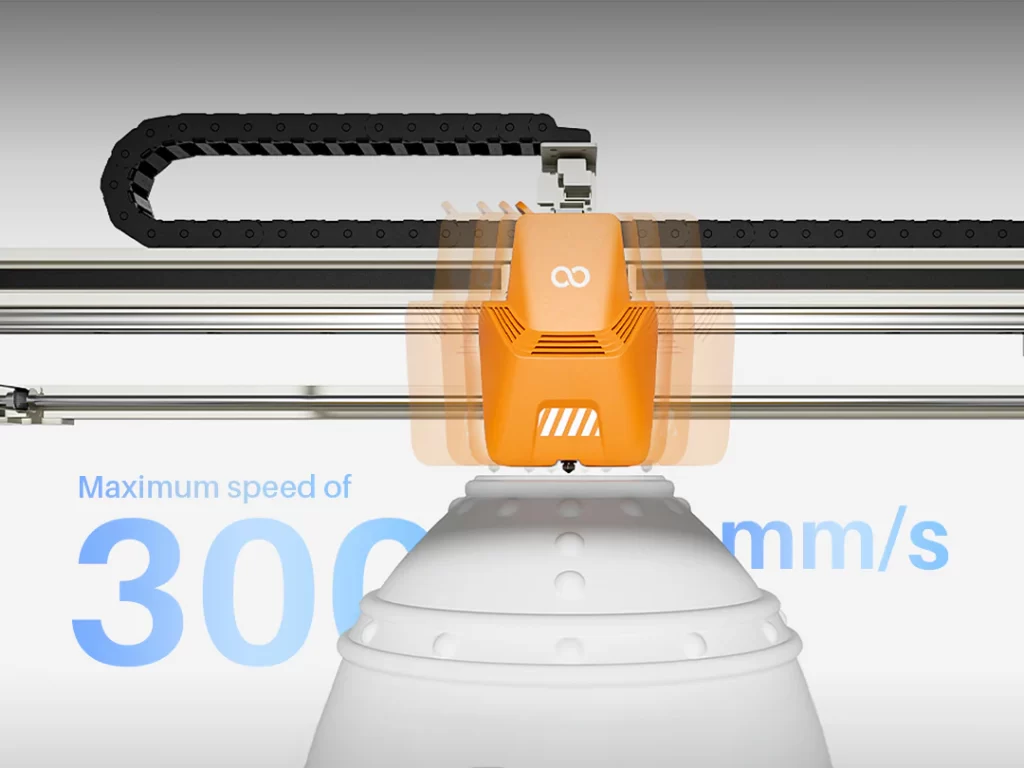

Fast Printing

Utilizing a 64-bit 1.5G clock speed quad-core high-performance processor (SOC RK3328), it provides sufficient computing capacity while delivering 6 times the printing speed, with a maximum speed of 300mm/s (150mm/s recommended), which is the top end print speed for printers of its size.

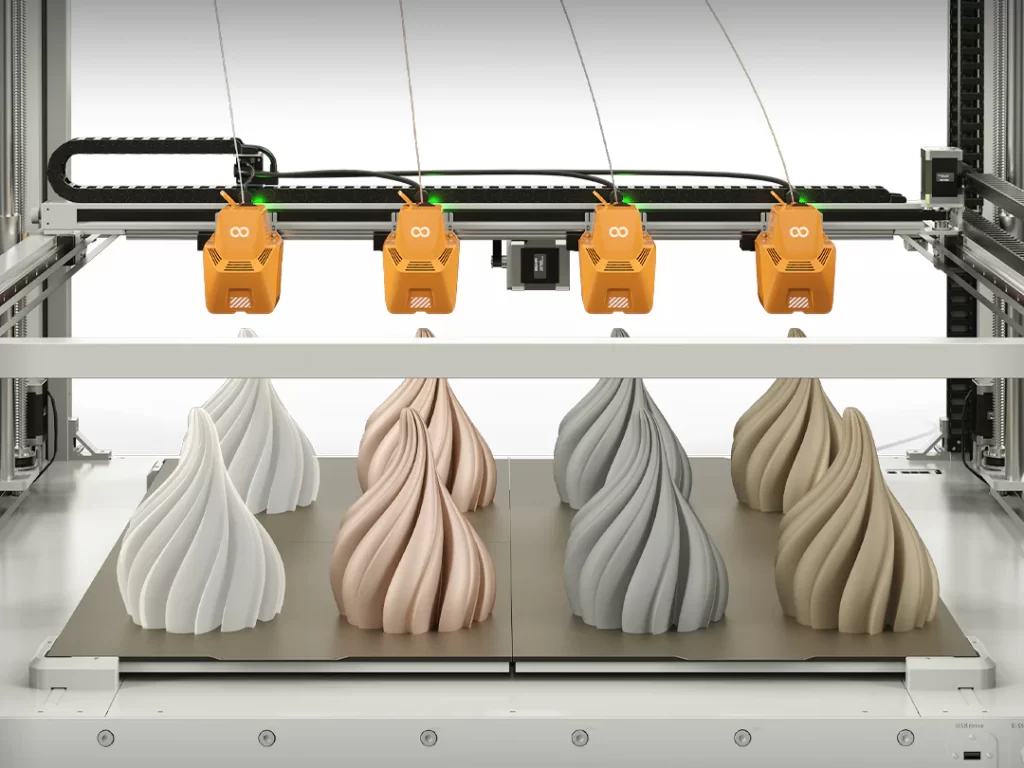

Multi- Nozzle Printing

Three additional printheads can be added to the X-axis to realize simultaneous printing with four nozzles, supporting printing four of the same model, while each nozzle can be equipped with the same material and different color filament to achieve four different colored models of the same kind.

The maximum power requirement is 1,530 W. For each additional printhead, an extra 100 W is needed. Please ensure that your setup can accommodate this total power load.

Powerful Cooling Fan

Thickened double-sided cooling fans can comprehensively enhance the model printing results. In addition, the fans are equipped with an intelligent control function that stops working when printing is complete, which saves energy and reduces noise as well as prolongs the lifespan. (5015 ball blower fan*2, 4010 ball axial fan*1)

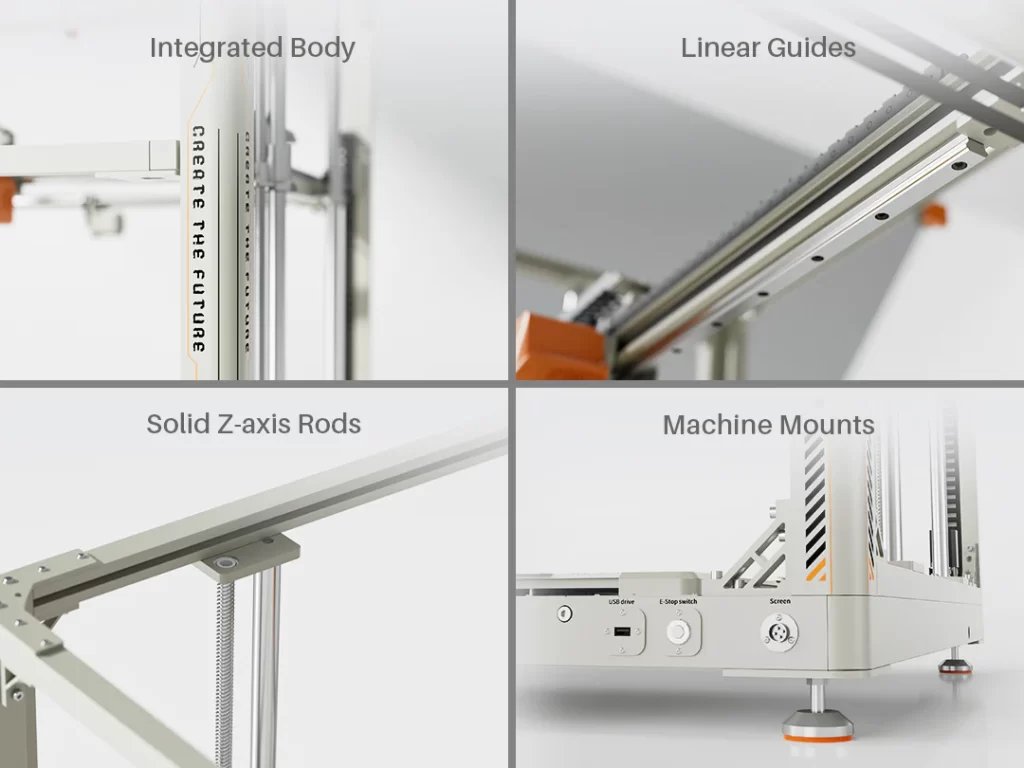

High-Quality Craftsmanship

Integrated body, elegant yet durable. The X-axis and Y-axis are linear guides, effectively improving printing stability and increasing lifespan. The Z-axis features an upgraded version of the Z-Axis rod to make the machine run smoothly and ensure leveling precision. Machine mounts are designed with a carbon steel round base and rubber round anti-slip pad bottom.

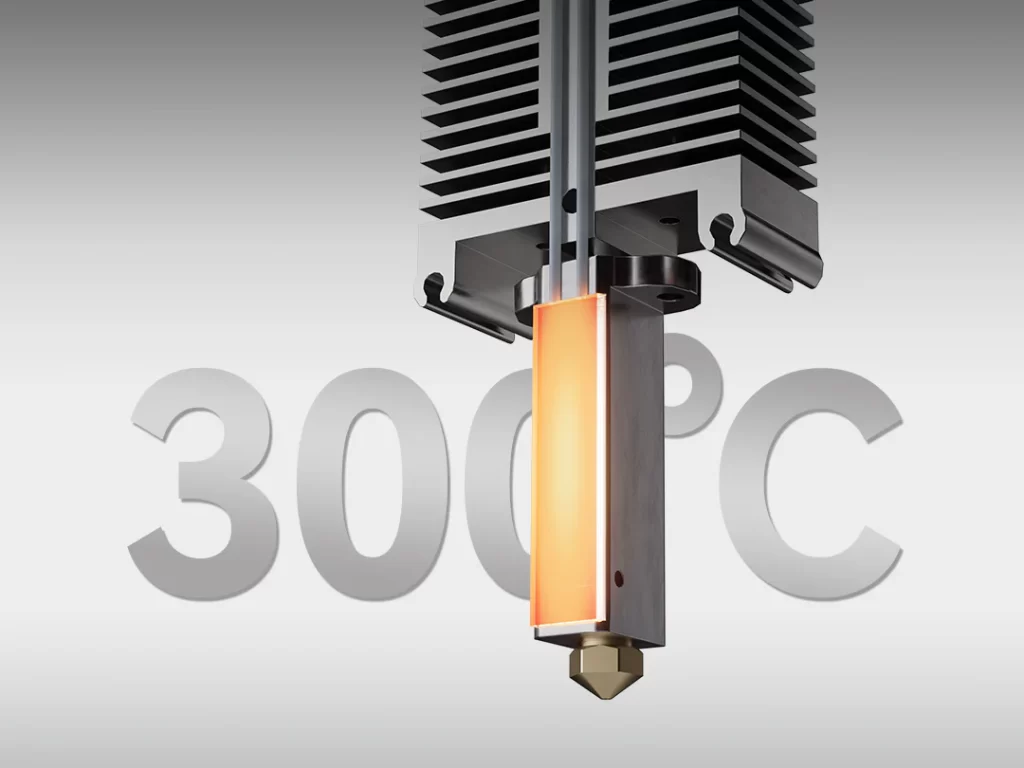

Powerful Extruder System

OrangeStorm Giga features a high-quality brass nozzle capable of reaching 300 °C, ideal for high-temperature materials. The dual-gear direct extruder and titanium heat break ensure consistent filament flow, while the 60 W ceramic heater provides rapid and stable heating.

Equipped with advanced PID auto-calibration and a built-in acceleration sensor, OrangeStorm Giga ensures exceptional print quality by maintaining precise temperature control and reducing vibrations. Create stunning results for all your projects with ease.

Nozzle Diameter (included): 0.6 mmNozzle Diameter (optional): 0.4 mm/0.8 mm/1.0 mm

Specification

Product Model

OrangeStorm Giga

Build Volume

800 × 800 × 1000 mm

Filament Compatibility

PLA / PETG / TPU

Printing Technology

FDM (Fused Deposition Modeling)

Printing Platform Size (PEI Area)

820 × 820 mm (4 independent 410 × 410 mm PEI plates)

Net Weight

104 kg

Frame Material

CNC machined aluminium extrusion

Machine Size

1,224 × 1,164 × 1,425 mm

Gross Weight

145 kg

Voltage

100-120 VAC/220-240 VAC, 50/60 Hz 1,530 W (single head; +100 W per additional head)

Package Size

Bottom + XY Axis Components: 1,350 × 1,215 × 420 mm Two Z-Axis Components: 1,350 × 1,215 × 350 mm

Resume Printing

Yes

File Transfer Method

USB, LAN, WIFI

Maximum Size For Machine Activity/MM

1,224 × 1,520 × 1,570

Filament Detection

Yes

File Format

STL, OBJ

Max. Nozzle Temperature

300°C

Max Speed of Tool Head

300 mm/s

UI Language

English, French, German, Russian, Italian, Spanish, Japanese, Chinese

Max. Hot bed Temperature

100°C (ambient temperature: 25°C)

Max Acceleration of Tool Head

5,000 mm/s²

Experience

Get Sample Parts

Enquiries To Buy

Your personal specialist will be in contact with you within the next 48 hours to discuss your enquiry.