Reliable C5 Grade Z-axis Module

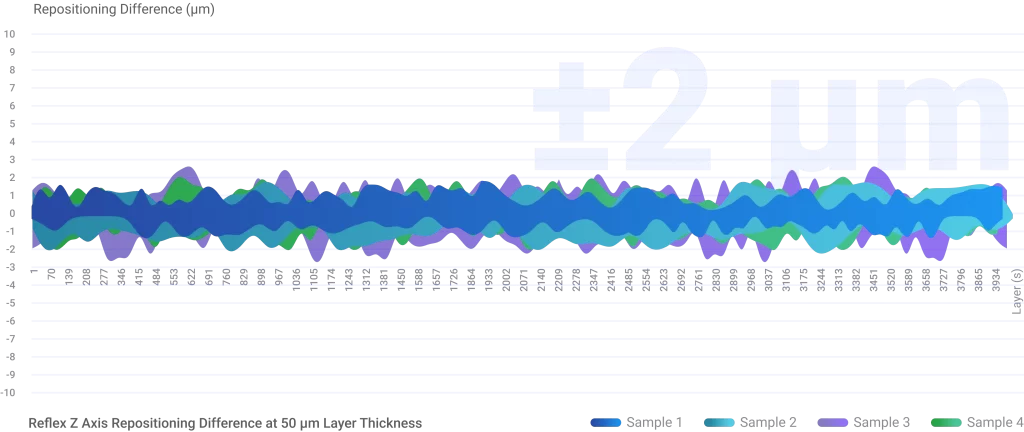

Z-axis Repositioning Variation at 50 µm Layer Thickness

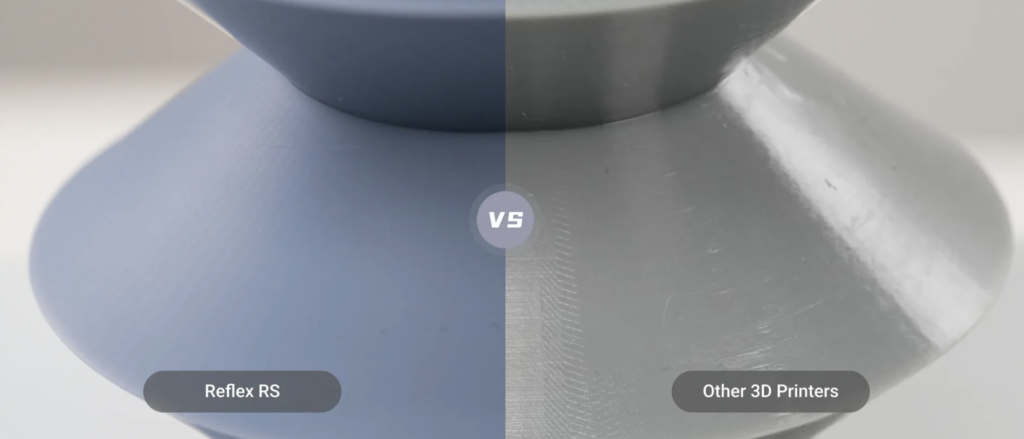

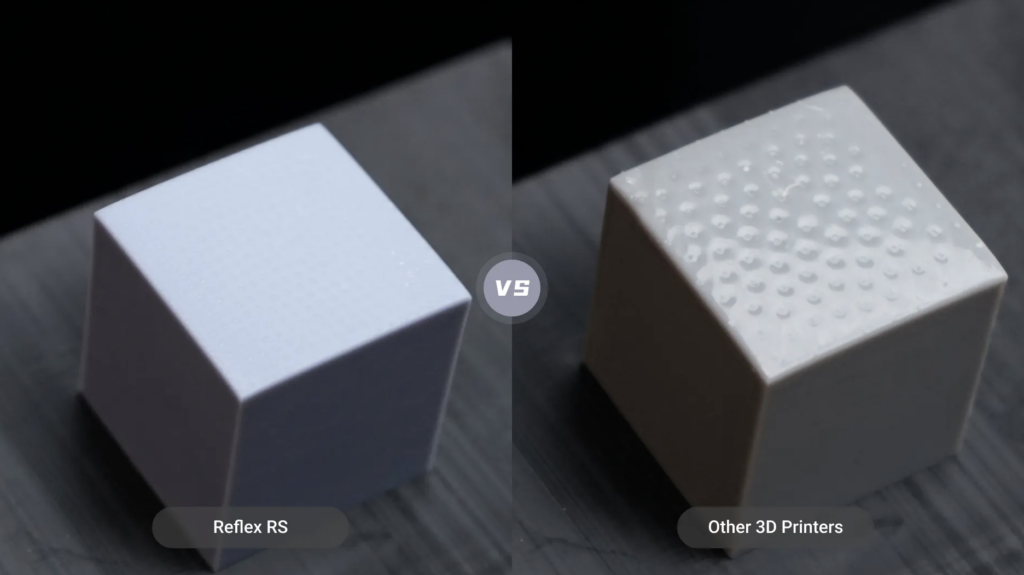

Test Model Results

*Data sourced from HeyGears Lab, 96% of movement errors are within 1 μm, and 99.9% of the errors are no more than 2 μm.

Full-Field Precision Screen

±3%

5%

Adaptive Z-axis Compensation

The process package allows the RS printer to adjust the Z-axis compensation adaptively for each resin, to support up to 180 combinations of different angles, hole sizes, and edge types.

HeyGears Reflex RS Resin 3D Printer

Compare HeyGears Reflex Series

Specifications

HeyGears Reflex RS

HeyGears Reflex

Hardware

LCD Screen

10.3 Inch 8K Mono Screen

9.25 Inch 6K Mono Screen

Light Source

405 nm Wavelength

365 nm Wavelength

Released Film

nFEP Film

nFEP Film

Z-Axis Module

C5 Grade Accuracy

C5 Grade Accuracy

Printing Data

Build Volume

222*122*230 mm

192*121*220 mm

Printing Speed (Tested with PAWW10 Resin)

Average Speed 4.5 Sec/Layer

Average Speed 12 Sec/Layer

Inteligent Technology

Automatic Leveling

240 µm Gap Leveling

240 µm Gap Leveling

Resin Automatic Refill

Resin Automatic Heating

Build in Heated Resin Tank

Heated Resin Tank (Sold Separately)

Residue Detection

0.2 mm Residue Detection

0.2 mm Residue Detection

Printing Monitoring

Force value Monitoring

Force value Monitoring

Released Film Life Span

Compatible Resin

Materials

PARP10, PAS10, PAWW10, PAP10, PARW10

PAU10, PAT10, PAM10, PAH10, PAU20, PAE10, PAC10, PAS10, PARP10, PAWW10, PAP10, PARW10

Others

Net Weight

20 kg

25 kg

Size

280*260*584 mm

400*420*572 mm

Experience

Get Sample Parts

Enquiries To Buy

Your personal specialist will be in contact with you within the next 48 hours to discuss your enquiry.

Enquiries To Buy

Your personal specialist will be in contact with you within the next 48 hours to discuss your enquiry.